Automatic control pulverized coal burner

|

| Characteristic: 1. Automatic ignition 2. Damper electric adjustment 3. Automatic temperature detection and adjustment 4. Motor rotation and electric back and forth motion 5. PLC touch screen control system |

|

1.Automatic ignition device |

| Oil tanker | Electric putter and electric firing gun |

|

|

|

2.Damper automatic adjustment—effectively reduce the coal consumption of burner Accurate control air flow can improve the combustion efficiency of pulverized coal. The best air volume for lkg coal is 10m³. Traditional burner by manual control air volume, which is inaccurate and uneasy to operate. Zhengzhou SINOSUN Machinery Co., Ltd. successfully developed automatic adjusting device. Electrical control the damper according to the coal supply, which effectively solve the problems of inaccurate air volume and incomplete burning. |

| Damper manufally control system | Damper eletric control system |

|

|

| 3.Burner Patented Design—easy for maintenance The combustion chamber automatically rotation by the motor to prevent furnace slagging and improve the service life of refractory brick. The traditional burner need clean the slag 3-4 days, but our company's design greatly reduces the burners’ repair work. Zhengzhou SINOSUN Machinery Co., Ltd. using split design, so combustion chamber and air supply device moving forward and backward on the pulley, which is easy for maintenance. This design has been conferred the national patent on Jul. 31, 2013. Patent number: ZL 2013 2 0054180.2 |

|

|

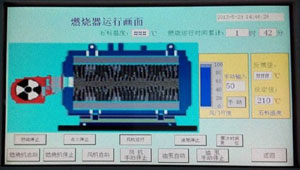

| 4.PLC touch screen automatic control system(SIEMENS) |

| SINOSUN’s coal burner can be equipped with PLC touch screen control system. The whole control process visualization, the operation is simple and convenient. Meanwhile interface can use English, Russian, etc. Continuous technological innovation and improving the customer satisfaction is SINOSUN’s unremitting pursue. We sincerely look forward to exchange and cooperation with users of burner industry at home and abroad. |

|